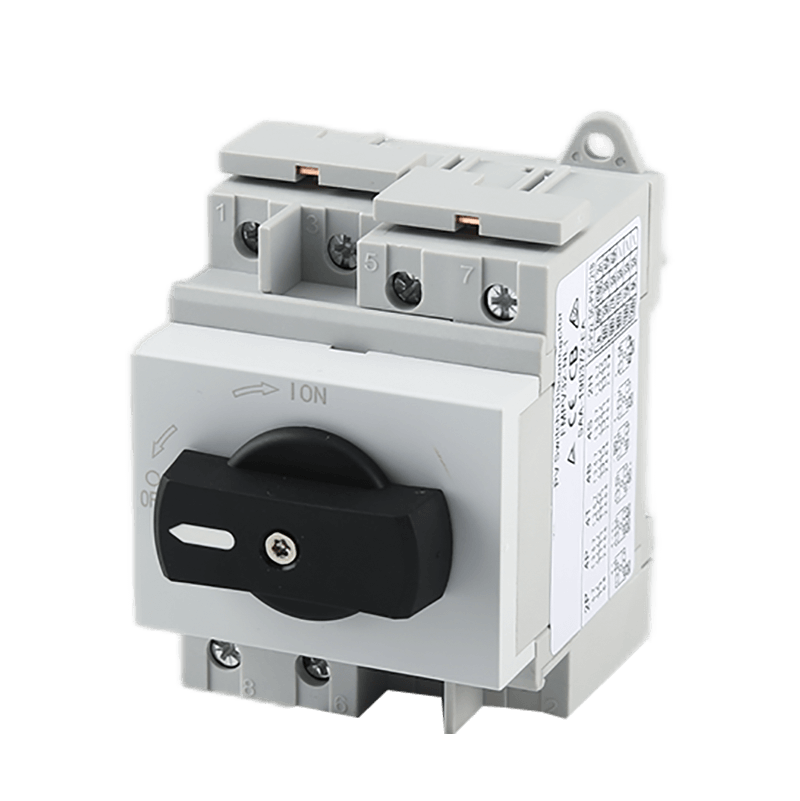

What is a 3 phase isolator?

A 3 phase isolator is an electrical switch used to isolate a circuit or device in a 3 phase AC system. It usually consists of three interlocked switches that control three live wires. The main function of a 3 phase isolator is to provide a safe way to disconnect a circuit from the power source for maintenance or repair while ensuring that there is no risk of electric shock.

What is the purpose of a 3 phase isolator?

3 phase isolators are widely used in industrial, commercial, and large residential applications. They are used to ensure that the power supply can be safely disconnected when equipment maintenance or emergency situations are being carried out. Common applications include:

Industrial machinery and equipment: used to isolate large machines and equipment for safe maintenance and repair.

Power distribution systems: used to isolate specific circuits or equipment in power distribution systems.

Renewable energy systems: such as solar energy systems, used to isolate solar panels from the rest of the system.

HVAC systems: used to isolate air conditioning equipment to prevent equipment damage during thunderstorms.

Applications of 3 phase isolators

3 phase isolators are very important in various applications, including:

Exhaust fans: In bathrooms or kitchens, exhaust fans usually require 3 phase isolators to completely isolate the power supply.

Electric water heaters: Electric water heaters installed in humid environments require isolators for safety.

Refrigerators: Especially large refrigerators, require isolators to reduce risks during maintenance and repair.

Air conditioners: It is recommended to install isolators for outdoor air conditioning units to prevent tripping during lightning strikes and faults.

Can 3 phase isolators be used on single-phase systems?

3 phase isolating switches can be used on single-phase systems in certain situations, but the following points should be noted:

Marking: According to the UL white paper, 3 phase circuit breakers are only suitable for 3 phase systems unless they are marked to indicate that they can be used on single-phase systems.

How to use: In single-phase systems, the two outer poles of the 3 phase isolating switch can be used to achieve disconnection.

Applicability: Make sure that the voltage and current ratings of the isolating switch are suitable for the requirements of the single-phase system.

In summary, 3 phase isolating switches are very important in industrial and commercial applications, providing a safe and reliable method of power isolation.

How 3 phase isolating switches ensure safety during maintenance

Provide physical isolation

3 phase isolating switches provide a physical isolation by disconnecting all three phases of power to the circuit. This means that when the switch is disconnected, the circuit is completely separated from the power supply, preventing any current from passing through, thereby ensuring that no current flows during maintenance, avoiding electric shock and other electrical hazards.

Prevent accidental reconnection

3 phase isolating switches are usually designed with a locking mechanism to ensure that the switch cannot be accidentally reconnected during maintenance. This locking mechanism can be a mechanical lock or an electrical lock, ensuring that only authorized personnel can reconnect the power, thereby preventing accidental electric shock accidents.

High visibility and clear identification

3 phase disconnectors usually have high visibility switch position indication and clear identification to help maintenance personnel quickly identify the switch status (open or closed). This design reduces the risk of misoperation and ensures that maintenance personnel can confirm that the power supply has been safely disconnected before operation.

Compliance with safety standards

3 phase disconnectors usually comply with strict safety standards, such as IEC 60947 or AS/NZS 60947. These standards specify the design, manufacturing and testing requirements of switches to ensure their reliability and safety under various operating conditions.

Protection level

Many 3 phase disconnectors have a high protection level (such as IP66) to ensure reliable operation even in harsh environments. This protection level prevents dust and water from entering the interior of the switch, ensuring its safety and reliability in outdoor or industrial environments.

Suitable for various applications

3 phase disconnectors are widely used in industrial, commercial and outdoor environments, and are suitable for various electrical equipment and systems, such as motors, air conditioners, refrigerators, etc. These application scenarios usually require a high level of safety and reliability, and 3 phase disconnectors meet these needs through their design and functions.

How often should a 3 phase isolator be inspected or maintained

The frequency of inspection and maintenance of a 3 phase isolator depends on the environment and operating conditions in which it is used. Here are some general guidelines:

Regular inspection and maintenance

Annual inspection:

Most 3 phase isolators should be fully inspected and maintained at least once a year. This includes visual inspection, functional testing, and replacement of any faulty accessories.

More frequent inspections:

In high-risk or harsh environments, such as construction sites or corrosive environments, the inspection frequency should be higher. For example, electrical installations on construction sites need to be inspected at least once a month.

In multi-tenant buildings or public places, electrical services should be inspected every six months to ensure public safety.

Specific maintenance activities

Visual inspection:

Inspect the external condition of the switch for any signs of physical damage, wear, or corrosion.

Inspect the cable terminal room and other appropriate rooms to remove surface contaminants on accessible solid insulation.

Functional testing:

Test the switch regularly with a multimeter to ensure accurate voltage readings.

Manually operate the switch to ensure that it operates smoothly without unusual noise or resistance.

Tightening inspection:

Inspect the tightness of connections and fasteners to ensure that all components are firmly in place.

Lubrication and Adjustment:

Inspect and lubricate the circuit breaker isolation mechanism to ensure proper operation.

Inspect and adjust the spring contact force and contact alignment.

Maintenance in Special Environments

Corrosive Environments:

In corrosive environments such as saltwater coasts, regular cleaning and inspection are particularly important to prevent corrosion and other damage.

High Temperature and High Humidity Environments:

In high temperature and high humidity environments, equipment ages faster and requires more frequent inspection and maintenance.

How to Troubleshoot Common Problems with 3 phase Disconnectors

1. Poor Contact and Overheating

Problem Description: The contact points of a 3 phase disconnector may overheat due to poor contact. This is usually caused by a small contact area or insufficient contact pressure between the static and dynamic contacts.

Solution:

Check the contact points for burnout or corrosion.

Sandpaper the contact points to ensure that the contact surface is flat and has a metallic sheen.

Apply conductive paste according to technical specifications to increase contact conductivity and prevent oxidation.

2. Mechanical Failure

Problem Description: The mechanical part of the disconnector may become stuck, loose, or deformed, causing the switch to not operate properly.

Solution:

Check whether the mechanical transmission part is loose, damaged or deformed.

Adjust the length of the operating link to match the closed position.

Ensure that the mechanical locking device works properly to prevent misoperation.

3. 3 phase asynchronism

Problem description: The 3 phase isolating switch may be asynchronic when opening or closing, resulting in the circuit not being completely opened or closed.

Solution:

Check and adjust the 3 phase synchronization of the isolating switch to ensure that the three phases operate simultaneously.

If necessary, use an insulating rod for adjustment, or apply for a power outage.

4. Overheating problem

Problem description: The isolating switch may overheat after long-term operation, which is usually caused by poor contact or excessive load.

Solution:

Clean the contaminants on the contact points and ensure that the contact surface is clean.

Apply conductive paste to increase contact conductivity.

If the overheating is severe, consider using a bypass circuit breaker for load transfer, or apply for a power outage.

5. Electrical failure

Problem description: The isolating switch may not operate normally due to electrical failure, such as a blown fuse or an abnormal electrical lock circuit.

Solution:

Check whether the power circuit and fuse are intact, and replace damaged fuses if necessary.

Check whether the electrical lock circuit is normal and ensure that all electrical connections are secure.

6. Insulation damage

Problem description: The porcelain insulator of the disconnector may be cracked or damaged, causing electrical leakage or short circuit.

Solution:

Check whether the porcelain insulator is cracked or damaged, and replace the damaged insulator if necessary.

Immediately isolate the faulty equipment and take safety measures when the insulator is found to be damaged.

Conclusion

In summary, a 3 phase isolator switch ensures safety by providing physical isolation, preventing accidental re-energization, and complying with safety standards. Regular inspection and maintenance are essential for its reliable operation.