Power surges are like electrical sneak attacks — sudden, short bursts of voltage that can wreak havoc on your system in the blink of an eye. Whether triggered by lightning, grid switching, or internal equipment faults, these spikes can quietly destroy sensitive electronics and cause expensive downtime.

That’s where AC Surge Protection Devices (SPDs) come in. Installed correctly, they serve as silent guardians that intercept excess energy before it can harm your equipment. This guide explains what they are, how to select the right type, how to size them properly, and how to keep them in top condition — with practical examples you can apply right away.

What is an AC SPD?

An AC SPD is a safety device designed to protect AC power systems from transient overvoltages — short-duration voltage spikes lasting microseconds but carrying potentially destructive energy.

Electrical surges originate from external sources (like a close lightning strike) or internal operations (such as motors cycling on/off or the switching of significant inductive loads). While they are brief, they can instantly damage microprocessors, control circuits, and insulation in wiring.

What does an AC surge protector do?

Surge Protective Device (SPD) operates on a principle analogous to a pressure relief valve, diverting transient overvoltages (surge energy) to earth. During standard operation, it remains passive within the circuit, permitting normal current flow unimpeded. When it detects a surge above its threshold, it instantly redirects the excess energy to earth, protecting downstream devices.

Example:

A commercial office has dozens of workstations and a server rack. One afternoon, a nearby lightning strike sends a 4,000V spike into the mains. Without SPDs, multiple systems could be lost. With SPDs, the excess energy is shunted harmlessly to ground within microseconds, avoiding data loss and equipment replacement costs.

How are Type 1, Type 2, and Type 3 surge protective devices categorized?

SPDs are classified by their installation location and surge-handling capacity. The right mix depends on your site’s risk profile and equipment sensitivity.

| Type | Installation Point | Application | Surge Energy Handling |

| Type 1 | At the main service entrance, before the main breaker | Provides the primary protection level against direct lightning impacts and major external surge events. | Highest capacity |

| Type 2 | Inside distribution boards after the main breaker | Protects branch circuits and equipment from residual surges | Medium capacity |

| Type 3 | Close to sensitive devices | Final layer of defense for electronics (e.g., plug-in strips for computers, medical devices) | Lowest capacity |

Case Study:

A plastics manufacturing plant in Malaysia installed Type 1 SPDs at the main incomer to guard against lightning. Type 2 units were added to sub-panels feeding injection molding machines, and Type 3 units were placed near PLC cabinets. After a severe monsoon storm, operations resumed without interruption. The maintenance team reported zero surge-related equipment failures — a strong return on a relatively small investment.

Voltage Ratings and Protection Levels

When choosing an SPD, three key parameters matter:

- Uc (Maximum Continuous Operating Voltage): The highest voltage level an SPD can sustain continuously without triggering its protective action.

- Up (Voltage Protection Level): Represents the peak voltage permitted to pass downstream by the SPD when suppressing a surge. Lower Up means better protection.

- Imax (Maximum Discharge Current): The highest surge current the SPD can safely divert during a standard test surge.

Practical Tip: For a 230V AC single-phase system, a Uc around 275V AC is common. It avoids nuisance tripping from minor fluctuations but still reacts to harmful surges.

Contrast: Choosing a Uc too close to your nominal voltage can cause false triggering, while choosing one too high can reduce protection effectiveness.

How do AC Surge Protection Devices SPD differ from Direct Current (DC) systems?

The difference boils down to the type of current they’re built for:

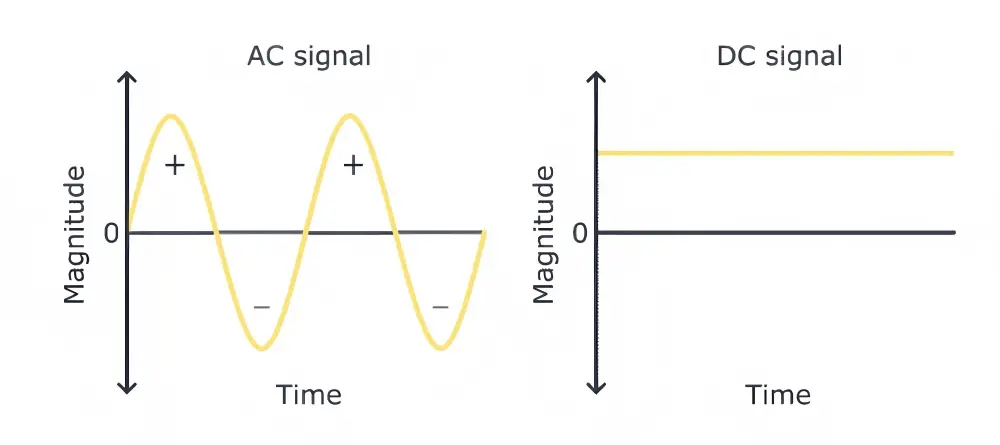

- AC SPD: Designed for alternating current, where the voltage and current periodically reverse direction.

- DC SPD: Designed for direct current, which flows in one direction only.

Because AC and DC stresses affect components differently, using the wrong type can cause overheating, continuous leakage current, or complete SPD failure.

Example:

A solar installer mistakenly fitted an AC SPD into a 1,000V DC PV array. Within weeks, the SPD overheated, leading to insulation damage and a costly repair. Using a DC-rated SPD would have avoided the problem.

Selection Process Based on Earthing

Your earthing arrangement (TN, TT, IT) directly affects how an SPD is wired and which ratings it should have.

- Within TN earthing configurations, the neutral and protective earth conductors establish a deliberate electrical bond at the supply transformer or distribution point. Protection is typically phase-to-neutral and phase-to-earth.

- TT Systems: Neutral and earth are separate; SPDs may require additional earth leakage protection to avoid tripping.

- IT Systems: No direct live-to-earth connection. SPD selection must account for insulation monitoring devices and floating systems.

Practical Rule: Always confirm the site’s earthing arrangement before ordering SPDs. Installing the wrong configuration can leave protection gaps and void equipment warranties.

Sizing and Coordination Principles

Correct SPD sizing ensures the device can handle real-world surge energy without failing prematurely.

Steps to correct sizing:

- Assess environmental and operational risk – Consider lightning strike density, building location, and presence of large inductive loads.

- Check nominal discharge current (In) – This is the current the SPD can handle repeatedly without degradation.

- Set Imax above your worst-case scenario – If your area averages high lightning currents, oversize accordingly.

- Use cascaded protection – Coordinate Type 1, Type 2, and Type 3 SPDs with proper separation distances (typically 10–15 m cable length) to share the energy load.

Example:

A hospital in Singapore, located in one of the world’s highest lightning-density regions, installed Type 1 SPDs rated at Imax 50kA at the main switchboard and Type 2 SPDs rated at 20kA in key distribution panels. During multiple storms, sensitive diagnostic equipment and life-support systems remained unaffected — a critical factor in patient safety.

FAQ

How to check if SPD is working or not?

A visual status window is common on SPDs, typically showing green for functional status and red to indicate end-of-life requiring replacement. Some also feature remote signaling contacts for integration into a monitoring system. Inspect them after severe storms or power disturbances.

How to test SPD with multimeter?

A standard multimeter can’t simulate surge events. However, you can measure continuity or insulation resistance if the SPD is disconnected. For accurate functional tests, use a surge generator or specialized SPD tester.

How do I know if my surge protector needs replacing?

Replace immediately if:

- The indicator shows red or blank

- There’s visible damage or burning

- The SPD has operated during a major surge event

Does a surge protector use a lot of electricity?

No. SPDs draw negligible power during normal operation — typically less than a small LED light.

How to Wire in AC SPD?

- Turn off main power.

- Mount the SPD close to the breaker or busbar.

- Connect line and neutral leads to the corresponding terminals.

- Connect the ground lead as short and direct as possible to minimize impedance.

- Restore power and check the indicator.

Quick Selection Checklist for AC SPDs from THOR

- Identify System Type – Single-phase or three-phase, correct pole configuration.

- Match Voltage Rating (Uc) – Equal to or slightly above system voltage.

- Select SPD Type(s) – Type 1 (service entrance), Type 2 (distribution), Type 3 (equipment).

- Check Key Specs – In (nominal), Imax (max surge), Up (clamping voltage).

- Verify Compliance – IEC 61643-11 or equivalent certification.

- End-of-Life Indicators – Visual window and/or remote signalling.

- Consider Joule Rating – Higher rating for longer life.

- Ensure Proper Wiring – Short, straight leads; correct cable sizes.

- Match Earthing Arrangement – TN-S, TN-C, TT, or IT compatibility.

- Plan Maintenance – Regular inspections and timely replacements.