What is DC MCB?

DC MCBs are specifically designed for circuits where the current flows in a constant direction.

Unlike alternating current (AC), direct current (DC) does not have natural zero crossings, which makes interrupting the circuit more challenging.

These miniature circuit breakers serve the same primary function as their AC counterparts: protecting against overloads and short circuits.

However, their design accounts for the unique characteristics of DC.

The working principle of a DC MCB is similar to that of an AC MCB, but since DC is unidirectional, the breaker does not need to adapt to changing current conditions.

DC MCBs are essential in various applications, including solar power systems, battery banks, and automotive electronics.

They provide reliable protection by interrupting the flow of electricity during overload or short circuit situations.

The thermal protection mechanism in a DC MCB activates when the current slightly exceeds the normal operating level.

In contrast, when a significant fault current occurs, the magnetic protection triggers an instantaneous trip.

A DC MCB can protect individual loads using DC power or safeguard main circuits such as inverters and photovoltaic battery packs.

These circuit breakers are crucial in DC power distribution systems, where they help prevent overcurrent conditions that could lead to equipment damage or fire hazards.

Key functions of DC MCBs include:

Interrupting current flow when it exceeds a predetermined threshold.

Protecting electrical components from damage due to excessive current.

Preventing electrical fires and other safety risks associated with overcurrent situations.

DC MCBs are widely applicable in renewable energy systems, electric vehicle charging stations, and battery energy storage systems.

They are designed to handle the continuous nature of DC electricity and often feature enhanced arc suppression mechanisms to manage the persistent arcs that occur when breaking the circuit.

Direct Current

Direct current (DC) is a type of electrical current that flows steadily in one direction.

Common examples include the current supplied by batteries, such as those used in flashlights and various electronic devices.

One notable advantage of alternating current (AC) over direct current (DC) is its cost-effectiveness in voltage transformation.

Additionally, AC experiences significantly lower energy loss when transmitted over long distances compared to DC.

This makes AC more suitable for widespread electrical distribution, as it can be easily stepped up or down using transformers, facilitating efficient transmission across vast networks.

The DC Circuit Breakers Working Principle

Current Detection

DC circuit breakers utilize a current sensing mechanism to monitor the current levels in a circuit.

This is typically accomplished with a built-in current sensor, such as a resistive current transformer (CT) or another type of sensor.

When the current surpasses a predetermined safety threshold, the sensor activates the circuit breaker’s protection mechanism.

Signal Processing

Upon detecting an abnormal current, the sensor transmits a signal to the circuit breaker’s control unit.

This unit assesses the signal to determine if action is necessary to interrupt the circuit.

Advanced DC circuit breakers may employ complex algorithms during this evaluation to differentiate between genuine faults and temporary fluctuations in current.

Circuit-Breaking Action

If the control unit concludes that the circuit should be opened, it triggers the mechanical or electronic switching component of the circuit breaker.

In mechanical breakers, this often involves a fast-acting spring mechanism that quickly separates the contacts, halting current flow.

In electronic versions, semiconductor devices like transistors or thyristors are used for rapid switching.

Arc Suppression

When breaking a circuit, arcing can occur as the current tries to maintain its path.

This arcing can generate high temperatures and potentially damage equipment or cause fires.

To mitigate this risk, DC circuit breakers are equipped with arc suppression devices that cool the arc rapidly and dissipate its energy, preventing damage to both the breaker and connected equipment.

Reset and Restore

After disconnection, the system can be safely inspected and repaired.

Once issues are resolved, the circuit breaker can be reset either manually or automatically.

Some models feature an auto-reset function that restores connections after confirming that it is safe to do so; however, certain failure types may require a manual reset for safety assurance.

Types of DC Circuit Breakers

DC circuit breakers are available in several types, each tailored for specific applications and featuring unique characteristics:

Thermal-Magnetic Circuit Breakers

These combine thermal and magnetic elements to provide protection against overcurrent.

The thermal component reacts to heat generated by sustained overloads, while the magnetic component responds to high current levels, ensuring effective protection in various scenarios.

Electronic Circuit Breakers

Utilizing electronic components, these breakers offer faster response times and adjustable settings for overcurrent protection.

They are ideal for applications requiring precise control and quick fault detection.

Hybrid Circuit Breakers

These integrate both mechanical and electronic components, providing rapid and reliable protection while reducing the likelihood of nuisance tripping.

Hybrid breakers are designed to handle high short-circuit currents efficiently.

DC miniature circuit breakers are categorized based on their tripping curves into Type B, Type C, and Type D:

Type B DC MCB

This type trips at a current of 3 to 5 times the rated current.

It is suitable for inductive or resistive loads with low switching surges, making it ideal for household and light commercial applications.

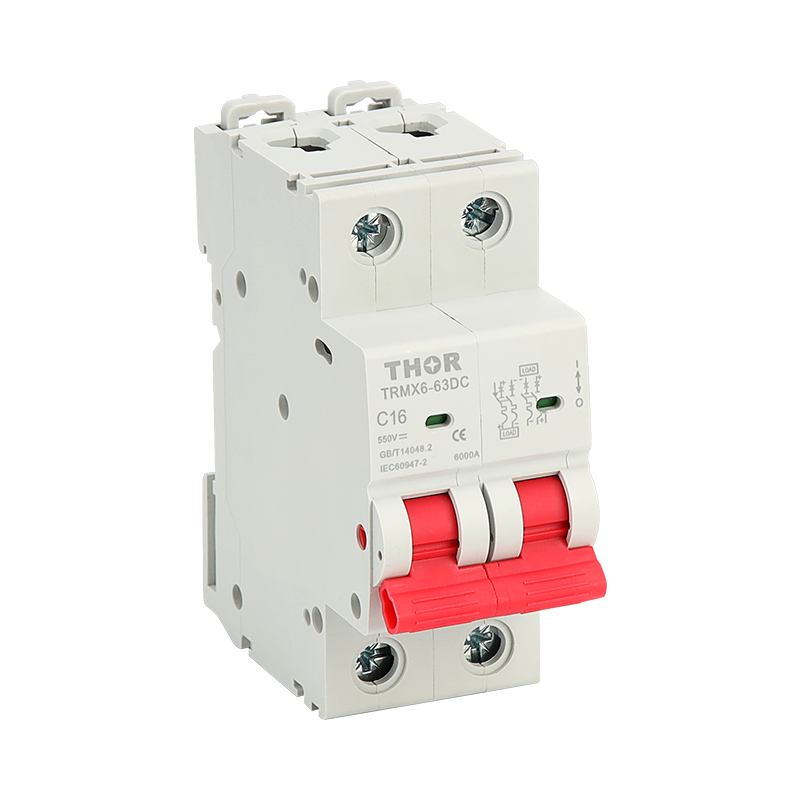

Type C DC MCB

Designed to trip at 5 to 10 times the rated current, Type C MCBs are commonly used in fluorescent lighting and small motors that experience higher inductive loads and switching surges.

They are well-suited for industrial and commercial environments.

Type D DC MCB

This type trips at 10 to 20 times the rated current and is typically employed for highly inductive loads with significant surge currents.

Applications include X-ray machines, uninterruptible power supplies (UPS), large winding motors, and industrial welding equipment.

Each type of DC circuit breaker serves specific functions based on the nature of the load and the electrical environment, ensuring safe operation across diverse applications.

How Do I Choose a DC Circuit Breaker?

Selecting the appropriate DC circuit breaker requires careful evaluation of several important factors to ensure it meets your specific needs. Here’s a step-by-step guide to assist you in making the right choice:

- Understand Your Application

- Identify the System Voltage: Determine the operating voltage of your DC system, which may include common voltages like 12V, 24V, 48V, 110V, 220V, and higher, especially in industrial and renewable energy contexts.

- Determine the Application Type: Consider whether the breaker will be used for residential, commercial, industrial, or renewable energy applications (e.g., solar photovoltaic systems).

- Determine the Current Rating

- Calculate the Full-Load Current: Sum the total current draw of all devices connected to the circuit to find the full-load current.

- Select a Breaker Rating: Choose a breaker with a current rating that is 125% to 150% of the full-load current to provide a safety margin and reduce the risk of nuisance tripping.

- Interrupting Capacity

- Check the Interrupting Rating: Ensure that the circuit breaker can safely interrupt the maximum fault current that may occur in your system. The interrupting capacity should exceed the maximum short-circuit current.

- Trip Curve and Characteristics

- Choose the Trip Curve: Select a trip curve (B, C, D, etc.) that aligns with your application needs. The trip curve dictates how quickly the breaker will trip during overload conditions.Type B

- Environmental Considerations

- Ambient Temperature: Consider the operating environment, as high temperatures can impact circuit breaker performance. Select a breaker that operates reliably within your application’s temperature range.

- Enclosure and Mounting: Decide on an appropriate enclosure type (e.g., NEMA or IP rating) if used in harsh environments, and consider mounting options (panel mount, DIN rail, etc.).

- Additional Features

- Remote Trip and Monitoring: If your application requires remote tripping capabilities or integration with monitoring systems, ensure that the chosen breaker supports these features.

- DC-Specific Characteristics: Confirm that the breaker is specifically rated for DC applications since AC and DC circuit breakers utilize different arc-extinguishing mechanisms.

- Compliance and Standards

- Check for Certification: Verify that the DC circuit breaker complies with relevant industry standards and certifications (e.g., UL, IEC) to ensure safety and reliability.