What Is a DC Isolator?

A DC isolator is a manually controlled device used to physically break a DC circuit for safety or servicing. It plays a crucial role in safety and maintenance by allowing sections of a DC system—especially in solar photovoltaic (PV) setups—to be safely powered down without disrupting the rest of the system.

How It Works

Unlike AC, which naturally crosses zero voltage points and is easier to interrupt, DC flows continuously in one direction, making arc suppression during disconnection significantly more challenging. To handle this, DC isolators are engineered with arc-quenching chambers, spring-loaded fast-action contacts, and magnetic blowout systems that safely break the circuit under load.

Real-world application: In a solar PV installation, DC isolators are installed between solar panels and the inverter. During maintenance, these switches allow technicians to isolate the high-voltage DC circuits safely without risking arc flash or damaging downstream components.

Key Differences Between DC and AC Isolation Devices

While AC and DC isolators share the same primary function—disconnecting power from a circuit—their internal designs and applications are quite different due to the nature of current flow.

- Current Type: AC isolators interrupt alternating current, which naturally reaches zero volts 100–120 times per second (depending on the grid). This makes arc extinguishing relatively easy. In contrast, DC current doesn’t zero out, making disconnection riskier without proper arc suppression.

- Contact Design: DC isolators often feature larger contact gaps, arc deflection chambers, and magnetic arc blowout systems to break current safely. AC isolators can use simpler contact mechanisms.

- Use Cases: AC isolators are commonly used in commercial HVAC systems, lighting, and industrial motors. DC isolators are essential in solar PV systems, battery banks, and EV chargers where consistent current flow is present.

Never substitute an AC isolator for a DC system. Fire hazards escalate due to the high probability of sustained arcing. Always choose a device rated for your specific voltage and current type.

What Is the Difference Between an Isolator and a Breaker?

Though functionally similar in disconnecting circuits, their underlying applications are inherently distinct.

An isolator is a manual disconnection device used for maintenance. It ensures that a section of the electrical system is physically separated from its power source. Isolators do not offer fault protection and should not be operated under load unless specifically rated for it.

Unlike manually operated disconnectors, circuit breakers provide autonomous protection through instantaneous fault response. It monitors current flow and trips during faults such as overcurrent, short circuit, or ground faults. Most circuit breakers are also capable of being manually operated, but their core function is fault interruption.

Think of the isolator as a padlock on a door you open before entering a machine room. The circuit breaker is the smoke detector that automatically triggers the fire suppression system when something goes wrong.

What Is the Main Purpose of an Isolator in a Power System?

The primary function of an isolator is to enable safe maintenance and operational flexibility in power systems.

It ensures that engineers and technicians can safely work on equipment without the risk of electric shock. Operational continuity is maintained via isolators’ segmented disconnection capability, which confines outages to designated subsystems.

Isolators are also used as part of lockout/tagout (LOTO) procedures in industrial environments, where safety and visibility of disconnection are non-negotiable.

Example:

In a solar farm, isolators are placed both at the array level and inverter input to allow quick shutdown in emergencies or during service inspections. In large commercial installations, isolators also serve to minimize downtime during routine checks or component replacements.

Types of DC Isolating Switch

DC isolators come in different configurations to meet various environmental, system, and safety requirements.

1. Rotary DC Isolators

User-activated via rotating handle to establish or break circuit connection. They are commonly used in solar systems, often mounted in IP-rated weatherproof enclosures. Rotary isolators offer visible disconnection and are ideal for outdoor installations.

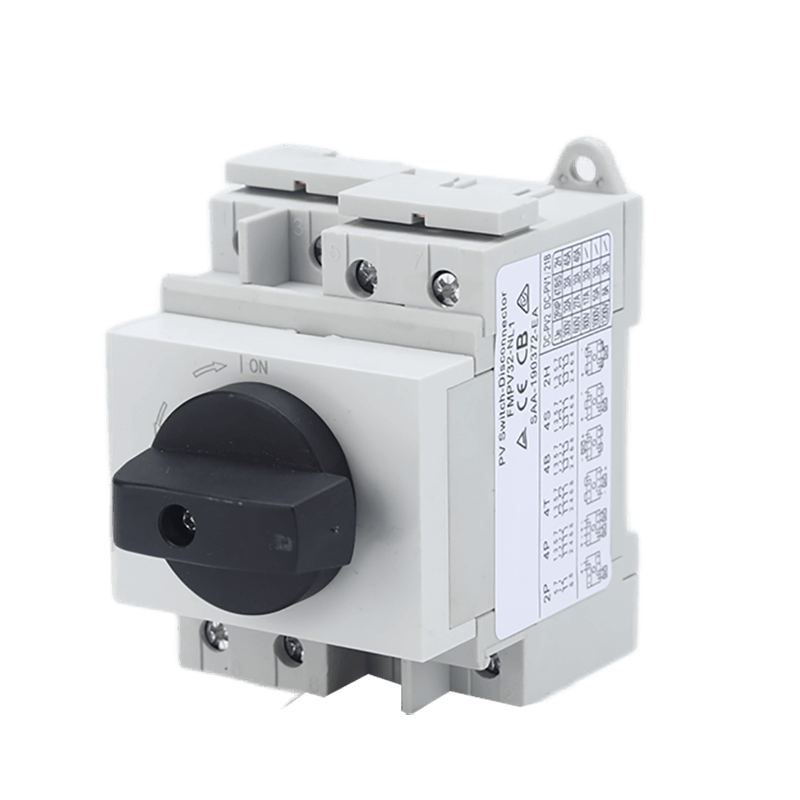

2. Modular Rail-Mounted Isolators

Designed for control panels and DIN rails, these isolators are compact and suited for indoor use. They’re commonly found in battery systems, DC power supplies, and industrial automation cabinets.

3. Enclosed DC Isolators

Pre-assembled with robust housings, these are built for harsh environments, including marine, mining, and EV infrastructure. Their enclosures are rated for IP66 or higher, protecting against water, dust, and UV exposure.

4. Load-Break DC Isolators

These isolators are engineered to disconnect circuits under load, thanks to advanced arc suppression technologies. They are used in applications where routine switching is necessary, such as DC motor control or off-grid systems.

In a commercial rooftop PV installation with a system voltage of 1000 VDC, rotary isolators are installed on the string side of the inverter. These switches enable technicians to isolate one string while others remain active—boosting safety without affecting power generation.

How to Choose the Right DC Switch-Disconnector for Your Application

Choosing the right DC isolator is not just about matching voltage and current—it’s about understanding the operational demands of your system and ensuring compliance with safety standards.

Key Selection Factors:

- Voltage & Current Rating: Make sure the isolator is rated for your system’s maximum DC voltage (e.g., 600V, 800V, 1000V) and current capacity. Underrated devices may fail under load.

- Number of Poles: DC systems often require 2-pole or 4-pole isolators to fully disconnect both positive and negative lines, especially in ungrounded (floating) systems.

- Enclosure Protection: For outdoor or industrial environments, choose isolators with IP66/IP67 protection to safeguard against dust, water, and UV degradation.

- Frequency of Operation: Some isolators are designed for emergency use only, while others can handle frequent switching cycles. Choose accordingly.

- Control Visibility: For maintenance crews, visible disconnection (either through mechanical indicators or a transparent window) helps verify circuit status at a glance.

Opt for isolators with LED status indicators or clear labeling—it reduces human error and speeds up maintenance.