What is a surge protective device?

Surge protective devices (SPD), also known as Transient Voltage Surge Suppressors (TVSS), are devices designed to limit transient voltages by diverting surge currents, thereby protecting low-voltage power systems from damage caused by transients, spikes, or surges. These devices are typically installed on the DIN rail of distribution panels.

In practical applications, surge protective devices are often used to safeguard sensitive electronic equipment prone to damage from transient overvoltages. This includes household devices such as computers, ovens, refrigerators, as well as systems like lighting systems and agricultural irrigation systems.

Do surge protective devices work?

Surge protective devices are useful as they can prevent damage to equipment downstream from voltage fluctuations or spikes caused by lightning or operational overvoltages. When people toggle a circuit breaker or an isolation switch on or off, the voltage in the circuit momentarily surges, and this transient process is referred to as operational overvoltage.

When the voltage exceeds the acceptable level for the equipment, surge protective devices utilize internal components such as Metal Oxide Varistors (MOVs) to absorb excess voltage and redirect it to the ground, preventing these surges from impacting the connected devices downstream. Due to this capability, high-quality surge protective devices serve as the best defense for safeguarding valuable equipment.

The same principle applies to lightning strikes. However, in cases of exceptionally large surges that could potentially damage the internal circuits of the surge protective device, it becomes necessary to replace the surge protective device to ensure continued protection in the future.

What devices should be on a surge protective device?

Surge protective devices play a crucial role in safeguarding electronic devices. Consideration needs to be given to devices that are sensitive to voltage fluctuations, expensive, or have data security requirements. Equipment such as medical devices or precision electronic devices often require more robust Surge Protective Device (SPD) protection. Additionally, in regions prone to frequent lightning and thunderstorms, there is a greater need for ample and reliable surge protection for electrical usage.

In general, surge protective devices should be employed to protect all devices with sensitive electronic components. In households, this includes devices like computers, televisions, refrigerators, ovens, audio systems, routers, and air conditioners. In industrial settings, equipment with sensitive electronic components, such as automated assembly lines, servers, sensors, communication devices, and electronic control units, also requires protection. In commercial applications, devices like computers, POS systems, switches, printers, payment terminals, and security systems fall into the category of equipment with sensitive electronic components.

To safeguard these sensitive electronic components, the adoption of surge protective devices is essential to implement electrical protection strategies, ensuring that devices operate efficiently and safely.

AC Surge Protective Device and DC Surge Protective Device

Based on the type of circuit protected, surge protectors can be classified into AC Surge Protective Devices (AC SPD) and DC Surge Protective Devices (DC SPD).

AC Surge Protective Devices (AC SPD):

AC circuits have voltage that varies periodically over time, following a sinusoidal function. The voltage changes in both magnitude and direction. Therefore, AC SPDs need to be capable of handling bidirectional voltage surges in AC circuits.

DC Surge Protective Devices (DC SPD):

In contrast, DC circuits have a constant voltage magnitude and direction since direct current does not exhibit periodic variations like alternating current. As a result, DC SPDs only need to handle unidirectional voltage surges in DC circuits.

AC SPD is designed to protect alternating current circuits and is typically installed near distribution boxes or electrical equipment, suitable for alternating current power systems. The rated voltage for AC SPD is usually 220V or 380V.

DC SPD is employed to safeguard direct current circuits and is commonly installed in photovoltaic combiner boxes, near inverters, or electric vehicle charging stations. It is suitable for direct current power systems. The rated voltage for DC SPD is generally 600V, 1000V, or 1500V.

T1 T2 T3 Surge Protective Device

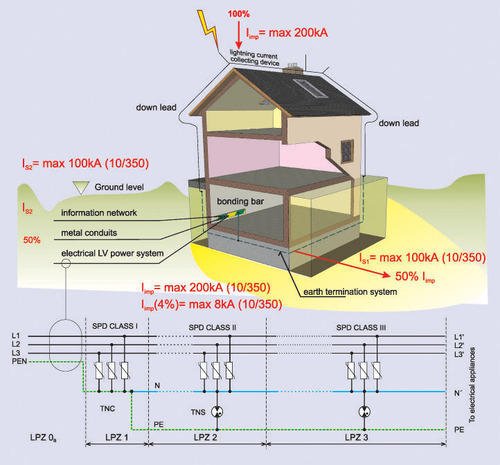

The Surge Protective Device (SPD) can be classified into T1, T2, and T3 based on three main characteristics: installation location, protection level, and surge handling capacity.

Installation location refers to where the SPD is specifically installed in the electrical system.

T1 SPDs are typically installed at the power entry point, often in the main distribution panel of an entire building. They serve as the first line of defense against external surges caused by lightning and other factors.

T2 SPDs are generally installed in sub-distribution panels within the building, positioned after T1 SPDs to provide a detailed second line of defense. Some surges may pass through T1 SPDs, and some surges may occur directly within the building.

T3 SPDs are typically installed near electronic devices, especially sensitive ones like computers, refrigerators, and medical equipment. T3 SPDs offer more precise surge protection, particularly for smaller surges and voltage spikes.

Protection level refers to the SPD’s defense against different magnitudes of surge currents.

T1 SPDs provide high-level protection and are designed to handle large surge currents, such as those caused by lightning.

T2 SPDs provide medium-level protection, handling smaller surge currents compared to T1 but still sufficient for most scenarios.

T3 SPDs offer low-level protection and are commonly used to safeguard sensitive electronic devices from subtle surges and voltage spikes.

Surge handling capacity is related to the surge current capacity of the surge protector. In an event triggered by a surge, the maximum surge current that a surge protector can allow through is its surge current capacity. This is essentially the upper limit of the surge protector’s protective capability.

T1 SPDs have a high surge handling capacity. T2 SPDs have a moderate surge handling capacity. T3 SPDs have a low surge handling capacity.

In practical applications, there are also combinations like T1+T2 SPDs and T2+T3 SPDs, providing protection against two different types of surges.

Certification standards for surge protective device

Certification standards are key objective factors for measuring the performance and material quality of surge protector products. Differences exist among these standards based on the country or region, primarily reflecting variations in power systems and electrical regulations.

Power Systems: Variations in power systems among different countries and regions result in differences in surge types and intensities. For example, differences in power systems with frequencies of 50Hz or 60Hz.

Electrical Regulations: Safety performance requirements for electrical products vary across countries and regions, leading to differences in certification standards for surge protectors. Examples include CE certification standards and UL certification standards.

Compliance with certification standards is crucial for ensuring the safety and regulatory compliance of surge protector products. Different application scenarios also have distinct requirements for surge protectors:

In industrial environments, surge protectors need higher tolerance for high temperatures and corrosion.

In medical environments, surge protectors must meet stricter safety and compatibility requirements.

International Standards:

IEC 61643-11:2011 – Surge protective devices for low-voltage electrical installations – Part 11: Requirements and tests for surge protective devices connected to low-voltage power systems

IEC 61643-12:2020 – Surge protective devices for low-voltage electrical installations – Part 12: Requirements and tests for SPDs for information and communication technology equipment

IEC 61643-21:2018 – Surge protective devices for low-voltage electrical installations – Part 21: Requirements and tests for SPDs for photovoltaic systems

IEC 61643-22:2016 – Surge protective devices for low-voltage electrical installations – Part 22: Requirements and tests for SPDs for electric vehicle charging systems

IEC 62305-3:2019 – Lightning protection – Part 3: Physical damage to structures and life hazard

North American Standards:

UL 1449 – Surge protectors

CSA C22.2 No. 269 – Surge protectors

European Standards:

EN 61643-11:2011 – Surge protective devices for low-voltage electrical installations – Part 11: Requirements and tests for surge protective devices connected to low-voltage power systems

EN 61643-12:2020 – Surge protective devices for low-voltage electrical installations – Part 12: Requirements and tests for SPDs for information and communication technology equipment

EN 61643-21:2018 – Surge protective devices for low-voltage electrical installations – Part 21: Requirements and tests for SPDs for photovoltaic systems

EN 61643-22:2016 – Surge protective devices for low-voltage electrical installations – Part 22: Requirements and tests for SPDs for electric vehicle charging systems

SPDs are classified into AC SPDs and DC SPDs based on the type of current flowing in the electrical system they are designed to protect.

Want to learn more about AC SPD: https://thorele.com/ac-spd-product-guide/

Want to learn more about DC SPD: https://thorele.com/dc-spd-product-guide/

Based on the installation location and the SPD’s ability to handle surge current, SPD can be divided into Type 1 SPD, Type 2 SPD, and Type 3 SPD.

Want to learn more about Type 1 SPD: https://thorele.com/type-1-surge-protective-device-spd/

Want to learn more about Type 2 SPD: https://thorele.com/type-2-surge-protective-device-spd/

Want to learn more about Type 3 SPD: https://thorele.com/type-3-surge-protective-device-spd/